Trustbridge connects you to a curated network of 3D printing service providers across the globe, delivering high-precision prototypes and end-use parts in record time. Whether you're iterating designs or scaling short-run production, our intelligent platform matches your requirements to certified additive manufacturing partners based on technology, material, lead time, and certification needs.

We support everything from FDM for cost-effective concepts to SLS, SLA, MJF, and metal 3D printing for industrial-grade parts — all backed by engineering review and supplier vetting. When quality, speed, and flexibility matter, Trustbridge is your go-to solution for professional 3D printing services.

What Tolerances Can You Expect?

What Tolerances Can You Expect?

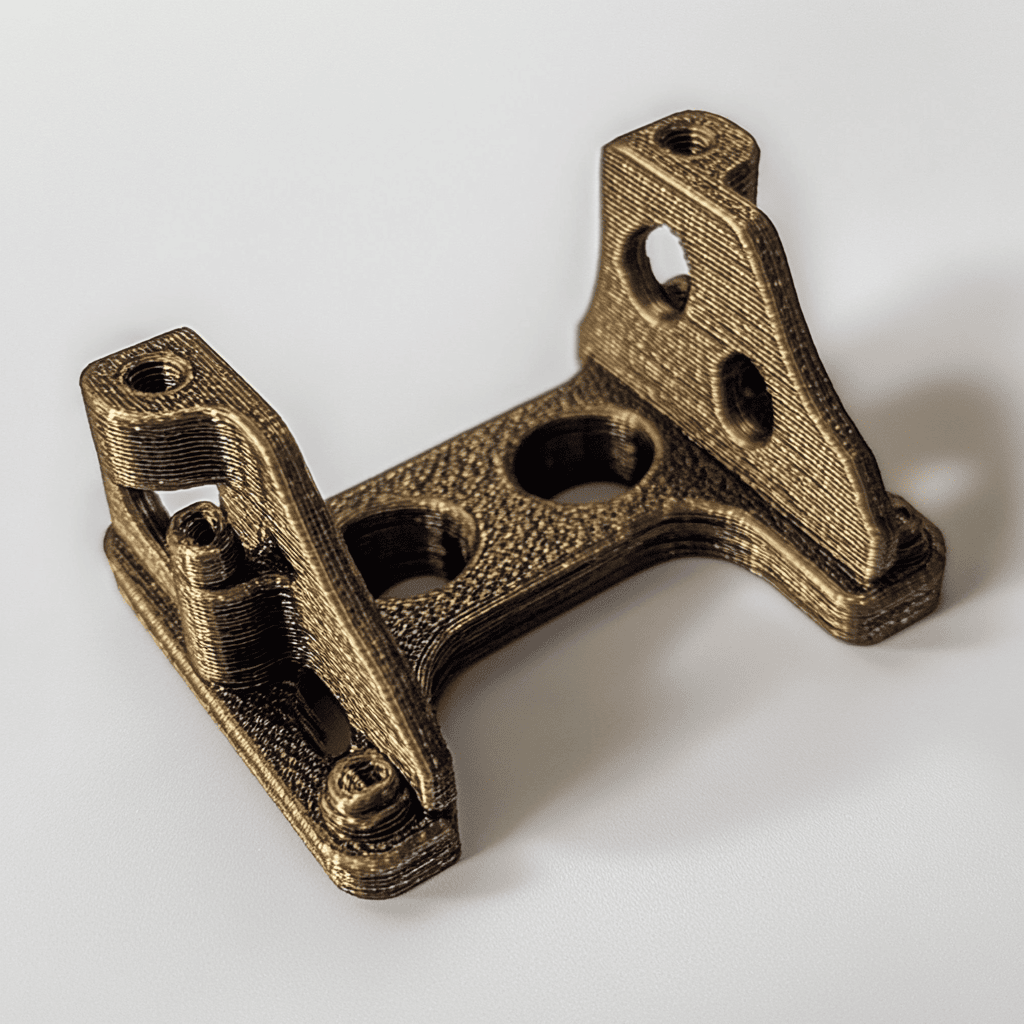

3D printing tolerances vary by technology and material, but our network consistently delivers industry-standard precision:

FDM/FFF: ±0.010 in or ±0.2 mm

SLA/SLS/MJF: ±0.005–0.008 in (0.13–0.2 mm)

DMLS/SLM (Metal): ±0.003–0.005 in (0.075–0.13 mm)

Surface Finish: From 200+ Ra (FDM) to 32–63 Ra (SLA/metal printing), with optional polishing or coating

We help you select the right printing process based on your part’s design intent and critical dimensions

Materials We Support in 3D Printing

Materials We Support in 3D Printing

Our global network supports a wide range of polymers, resins, and metals:

Thermoplastics (FDM/FFF): PLA, ABS, Nylon (PA11, PA12), PETG, TPU, PC

Powder-Based Polymers (SLS, MJF): PA12, PA12-GF, PA11, PP

Photopolymers (SLA/DLP): Tough, Flexible, High Temp, Castable, Biocompatible resins

Metals (DMLS/SLM): Stainless Steel (316L), Aluminum (AlSi10Mg), Titanium (Ti64), Inconel, Tool Steel

Composites: Carbon fiber-filled nylon, fiberglass-reinforced polymers

Need guidance? Our engineers help match performance and cosmetic requirements to the right materials and processes.

Technologies in Our 3D Printing Network

Technologies in Our 3D Printing Network

We support every major 3D printing process, from concept to production-grade output:

FDM (Fused Deposition Modeling): Cost-effective prototyping, large-format parts

SLS (Selective Laser Sintering): Strong, unfilled or glass-filled nylon parts with excellent surface quality

MJF (Multi Jet Fusion): High repeatability for production-grade thermoplastic parts

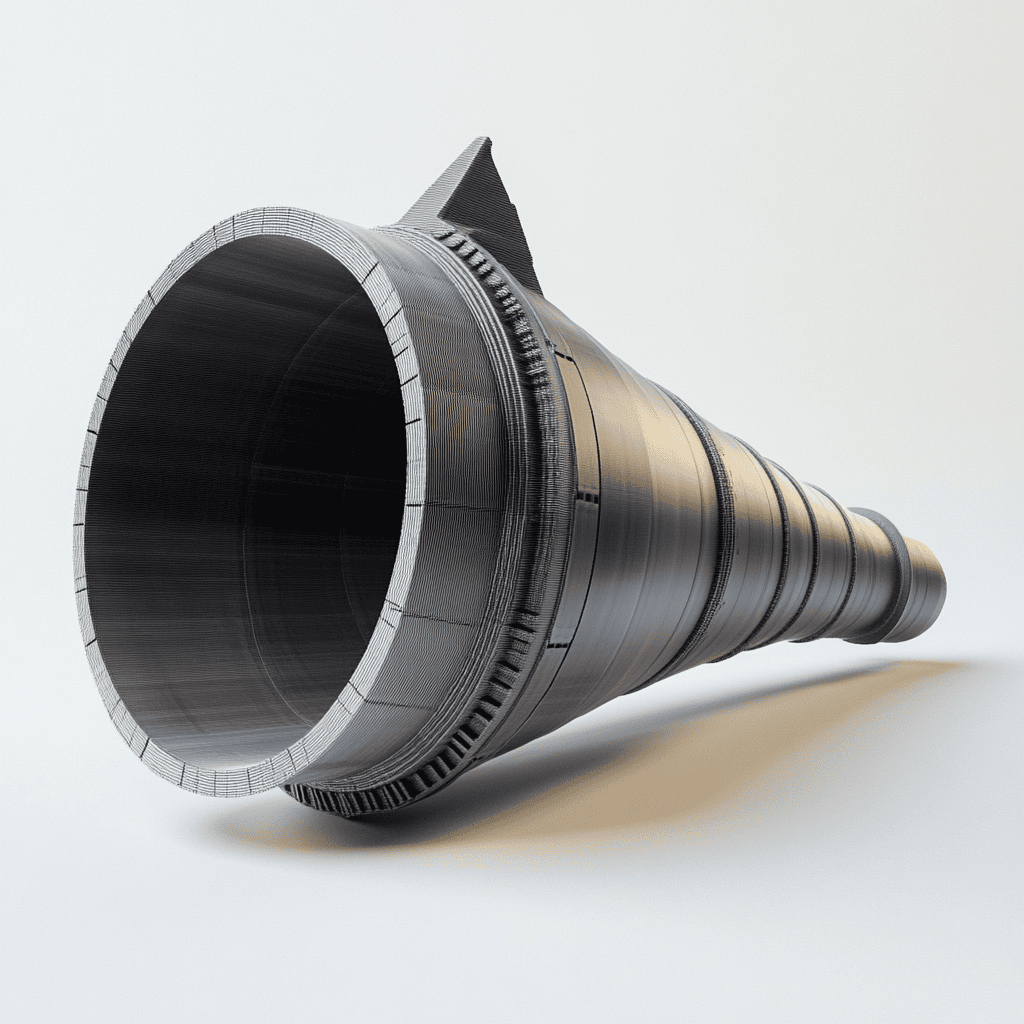

SLA (Stereolithography): High-detail, smooth-surfaced parts and functional resins

DMLS/SLM (Direct Metal Printing): Functional end-use metal parts in aerospace, medical, and industrial sectors

Carbon DLS / HP Jet Fusion / PolyJet: For special applications needing elastomers, color, or ultra-smooth finishes

From prototyping to full production, we pair your part with the best-fit technology.

Industries We Serve

Industries We Serve

Trustbridge 3D printing supports demanding use cases across:

Aerospace & UAVs

Medical Devices & Dental

Consumer Electronics

Automotive & EV

Robotics & Industrial Automation

Footwear & Apparel

Architecture & Product Design

Our partners are equipped for projects ranging from concept validation to production-grade, end-use parts.

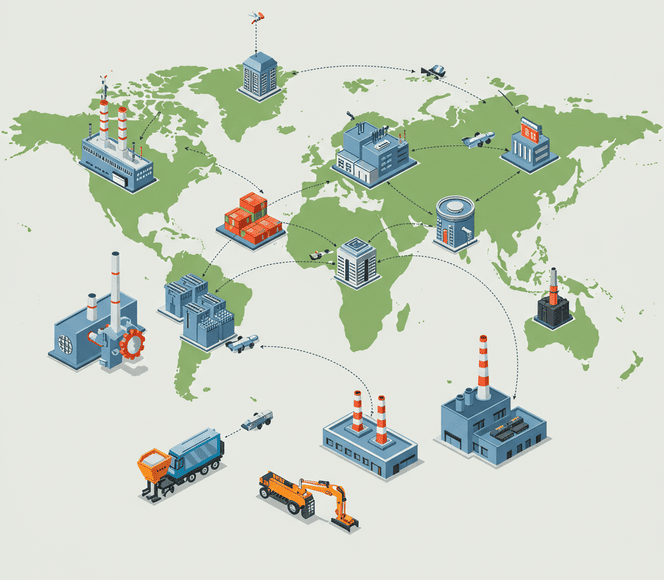

Our Global Supplier Network

Our Global Supplier Network

You get access to hundreds of additive manufacturing partners, pre-vetted for performance:

300+ 3D printing facilities across the U.S., Europe, and Asia

Technologies spanning 8+ additive processes

70% ISO 9001 certified; many ISO 13485 and AS9100 certified

Local and regional rapid-turn capacity in major metros

On-demand scaling for prototyping, pilot runs, or production

All vendors are audited, performance-scored, and monitored — so you get consistent results, every time.

Case Study Highlight

Case Study Highlight

Customer: Medical Device Startup

Service: SLA & DMLS 3D Printing

Challenge: Needed 10 plastic prototypes + 3 functional titanium brackets in 5 days

Solution: Trustbridge routed parts to a U.S. SLA resin specialist and a certified metal printing partner

Result: All parts delivered ahead of schedule; parts passed clinical and functional evaluation

“The turnaround and quality exceeded expectations — exactly what we needed for our pitch and pilot.”

— VP of Product Development, HealthTech Company

Frequently Asked Questions

How do I choose the right 3D printing process?

Submit your files and project goals — our team will recommend the ideal process and material.

Do you offer color or finishing options?

Yes — we offer dyeing, painting, polishing, vapor smoothing, and multi-color print processes like PolyJet and HP Jet Fusion.

Can you handle metal 3D printing?

Absolutely. We support DMLS/SLM for titanium, stainless steel, aluminum, and Inconel.

What is the minimum order quantity?

We support single-unit prototypes, small batch runs, and scaled production — no MOQ required.

Why Work With Trustbridge?

Why Work With Trustbridge?

Expert Matching Across 3D Printing Technologies

From FDM to SLS to DMLS, we match your project to the right process and supplier — whether you need fast, low-cost concept models or production-grade functional parts. No guesswork. No trial and error.

Hands-On Engineering Guidance

Not sure if your part is best suited for MJF, SLA, or FDM? Our team helps you select the optimal technology, orientation, and material — and ensures your design is printable and purpose-fit before it hits the machine.

Transparency Into the Shop Floor

You know who’s printing your parts. Trustbridge connects you directly with vetted additive manufacturers, so you can choose based on capability, material access, finish quality, and turnaround time — not just a faceless quote.

Better Pricing Without the Bloat

We strip out unnecessary middlemen and platform fees. By working directly with additive suppliers and only stepping in where needed, you save 30–50% compared to conventional brokered solutions — without sacrificing speed or quality.

Global Network, Local Delivery

Need ultra-fast turnaround in the U.S.? Or cost-effective scaling through an overseas supplier? We give you access to a global network of qualified 3D printing partners — with the engineering support to make it seamless.